Adhesive Resin for Aluminum-plastic composite pipe

Multilayer Composite Structure of Aluminum-Plastic Pipes

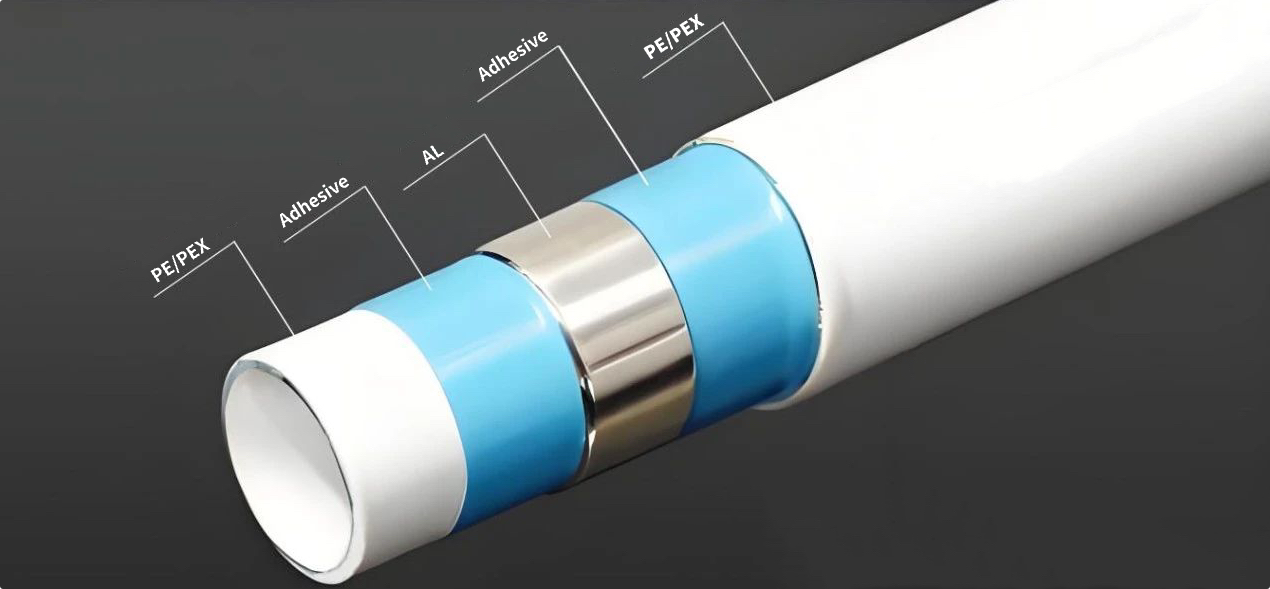

Aluminum-plastic composite pipes (referred to as aluminum-plastic pipes) feature a five-layer structure. By combining polymer materials with metal layers, they integrate the flexibility of plastic pipes with the strength of metal pipes. The structure is as follows:

- Inner Polyethylene Layer (PE/PEX): Directly contacts the transported medium (e.g., water, gas), requiring corrosion resistance, smoothness, and non-toxicity.

- Inner Bonding Resin Layer: Bonds the inner plastic layer to the intermediate aluminum layer, preventing medium penetration or chemical corrosion-induced delamination.

- Intermediate Aluminum Layer: An aluminum alloy sheet acts as the pipe’s skeleton, providing high strength, pressure resistance, gas impermeability, and bendability without rebound.

- Outer Bonding Resin Layer: Ensures tight adhesion between the aluminum layer and outer plastic, resisting external environmental factors (e.g., UV rays, acids, alkalis).

- Outer Polyethylene Layer (PE/PEX): Protects the aluminum layer from mechanical damage and chemical corrosion.

We supply the bonding resin layers in this five-layer structure. The performance of aluminum-plastic pipes directly depends on material quality and bonding processes.

Why Choose Our Bonding Resins for Aluminum-Plastic Pipes?

-

Superior Interlayer Bonding Strength for Structural Integrity

Our resins utilize unique molecular designs to form chemical bonds with aluminum layers and polyethylene (PE/PEX) layers, achieving seamless, high-strength adhesion. Testing shows peel strength at the bonding interface meets industry-leading standards, effectively preventing delamination under high pressure, temperature fluctuations, or external impacts, ensuring long-term stability. -

High-Temperature Resistance and Durability for Harsh Environments

Designed for high-temperature water supply and underfloor heating systems, our resins incorporate heat-resistant modifiers to maintain performance from -40°C to 110°C, withstanding long-term thermal-oxidative aging and UV exposure. Even under thermal cycling, the bonding layer retains flexibility and adhesion, eliminating cracks caused by thermal expansion and contraction. -

Process Compatibility for Enhanced Productivity

Optimized for high-speed extrusion, our resins feature rapid melting and low-viscosity flow, ensuring seamless integration with co-extrusion lines for stable, continuous coating. With a tailored processing window, they reduce energy consumption and defect rates, driving cost efficiency.

Broad Applications for Diverse Needs

Our bonding resins are suitable for various aluminum-plastic pipes, including:

- Building Water/Gas Systems: Cold/hot water pipes, gas pipes.

- HVAC Systems: Underfloor heating pipes, radiator connections.

- Industrial Fluid Transport: Chemical medium pipes, compressed air pipes.

- Solar/Heat Pump Systems: High-temperature-resistant circulation pipelines.

Choosing Our Bonding Resins Means Choosing Quality and Trust!

As piping systems evolve toward high performance and longevity, we continue to innovate materials to advance the industry. Whether for new projects or upgrades, our resins empower your competitive edge.

Contact us today for samples, technical solutions, and collaboration in building safer, more durable aluminum-plastic pipe systems!

FOSHAN LIAOFAN PLASTIC INDUSTRY CO., LTD.

FOSHAN LIAOFAN PLASTIC INDUSTRY CO., LTD.